Indonesia has been dubbed the world’s best producer of coconut charcoal briquettes. Obviously, such a title came not without reason.

Worldwide charcoal buyers reported at international trade shows that Indonesian coconut charcoal briquettes have the best quality in the world amongst those produced by other countries. They travel thousands of miles all the way to Indonesia in search of the best coconut charcoal briquettes for their market. It is not surprising that Indonesia is currently meeting more than half of the world’s total demand for coconut charcoal briquettes, with USD $227 million in export value in 2020 and an annual growth rate of around 4%. And the number continually increases year by year.

So, what makes Indonesia’s coconut charcoal briquettes highly sought after in the international market?

There are a few factors that give Indonesia unfair advantages when it comes to producing the best coconut charcoal briquettes in the world.

First and foremost, the country’s land is extremely fertile and well-suited to the mass production of coconuts. With year-round warmth and humidity, the tropical climate is ideal for the development of coconut trees. The evenly distributed rain in Indonesia also ensures that the trees provide the necessary water to grow and thrive. The country’s extensive coastal areas and topography make it ideal for growing coconut trees, enabling the creation of many different varieties of coconuts with distinct qualities.

The high quality of Indonesia’s raw materials is the main factor that makes its coconut charcoal briquettes stand out. The high-quality raw materials provide a solid foundation for producing coconut charcoal briquettes with outstanding characteristics, such as high heat output, minimal ash content, and a clean burn.

Indonesia has also developed its own special methods and skills for handling and processing these coconut raw materials. Over the years, the country has established itself as a leader in the production of coconut charcoal briquettes by meeting over 80% of the world’s demand for shisha charcoal to date. The high-quality coconut raw materials are turned into world-class briquettes with consistent quality by skilled artisans using proprietary techniques that have been developed through decades of innovation and development.

Raw Materials

Premium coconut charcoal briquettes are made of 100% natural coconut shell charcoal, with no harsh, artificial chemicals or wood mixes. High quality coconut shell charcoal produces high quality coconut charcoal briquettes. To get the finest quality coconut charcoal briquettes, it is very important to first prequalify the quality of coconut shells used for manufacturing the coconut shell charcoal. The shell quality has a major impact on the ash content, ash color, burning time, flavor and odor all of which lead to a reliable and enjoyable smoking experience.

Coconut trees grow all over Indonesia. While they come from the same species, the coconut shell properties vary from one island to another depending on the soil properties on which the coconut trees grow and the time of harvest. The best coconut shells are arguably from Sulawesi and some regions in Sumatra as they produce white ash with low ash content. Coconut shells from Java on the other hand produce very dark ash with very high ash content around 7-15%. To get good quality ash, coconuts should be harvested during the dry season between May to September. When harvested during the wet season, the resulting coconut shell charcoal will be darker in color with a higher ash content.

Burning Method

Once high quality coconut shells are collected, they need to be burned or “carbonized” to produce coconut shell charcoal. The burning method is the second most important factor that influences the quality of the coconut shell charcoal. It is best to burn coconut shells in steel drums in a low oxygen environment as opposed to burning them openly on the ground or in earth pits. This ensures the resulting coconut shell charcoal contains a high carbon percentage of over 80% and high calories.

Cooling Method

The best way to end the carbonization is to let the flame die out on its own without intervention, also called the “dry method”. It allows the coconut shell charcoal to be fully carbonized resulting in a low moisture content and high calorific value.

As the dry method takes a relatively long time, a lot of farmers tend to pour water into the steel drums to extinguish the flame instantly. However, this causes a lot of half-burned shell charcoal with very high moisture from the water. Therefore, this “wet method” should be strongly avoided.

To combine the advantages of the “dry method” and the “wet method”, some farmers use the “sprinkle method” whereby they sprinkle water to end the carbonization process. It is similar to pouring water but with a lot less water and faster cooling time than the dry method. They subsequently dry the coconut shell charcoal under the sun to remove a lot of the moisture absorbed from the water during the cooling period.

Storage

Coconut shell charcoal must also be stored under shelter to protect it from direct sunlight, extreme heat and rains that would otherwise deteriorate its quality and reduce its shelf life.

Prolonged exposure to high temperatures can cause the charcoal to crack, crumble, or become brittle, making it less effective as a fuel source. Storing the coconut shell charcoal away from direct sunlight and extreme heat preserves its physical properties.

Charcoal is highly porous and can easily absorb moisture from its surroundings. When exposed to rain or high humidity, charcoal can become damp, making it difficult to ignite and sustain a consistent burn. Moisture also promotes the growth of mold and mildew on the charcoal, which can make these spots difficult to burn. Low-quality or damp charcoal may also introduce undesirable odors or flavors that might negatively impact the shisha’s taste. Charcoal that is stored in a sheltered area stays dry and free of moisture, so it is always ready to use.

In a nutshell, premium coconut shell charcoal has a high carbon percentage (up to 85%), low moisture (below 12%) and low ash content (3-7%). These are the standards that top Indonesian manufacturers use to produce the world’s best coconut charcoal briquettes that are dominating the market to date.

What do potential buyers need to know about buying coconut charcoal briquettes?

Let’s examine the key indicators that influence the quality of coconut charcoal briquettes.

Fixed Carbon

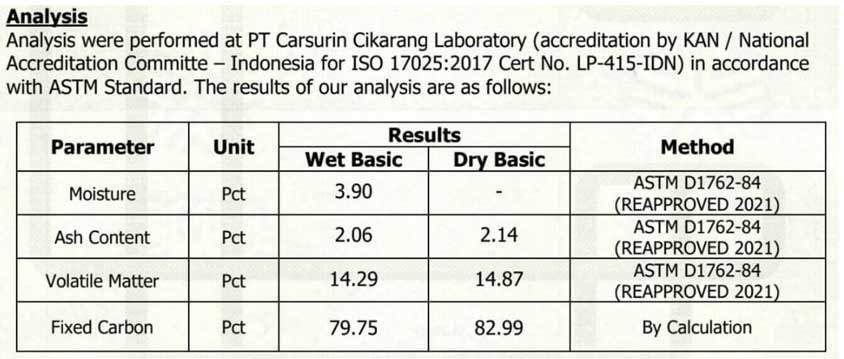

Fixed carbon refers to what is left in the charcoal after the carbonization process has removed the water, gases, and impurities that are volatile. It includes carbon content that provides the primary source of heat when the charcoal burns. Coconut charcoal briquettes that are made of fully carbonized coconut shell charcoal in a low-oxygen environment tend to have a high percentage of carbon of around 80%. As shown in the above test report by Carsurin Laboratory, the fixed carbon percentage of our coconut charcoal briquettes is 80 – 83%.

The fixed carbon content directly impacts the heat output of the coconut charcoal briquette. A higher fixed carbon percentage generally means that the briquette will produce more heat when burned. This is essential for achieving and maintaining the optimal temperature for shisha smoking.

Coconut charcoal briquettes with a higher fixed carbon percentage also tend to burn more consistently and evenly. They act as a stable and predictable heat source, which is essential for a satisfying shisha session. Inconsistent or fluctuating heat can lead to a less enjoyable smoking experience.

Coconut charcoal briquettes with a higher fixed carbon content typically have a longer burning time. This means you can use fewer briquettes to maintain the desired heat level, which can be more cost-effective in the long run. They also produce less ash which is desirable as excessive ash can clog the hookah bowl and affect the draw and flavor of the shisha tobacco.

A higher fixed carbon percentage is often associated with higher-quality coconut charcoal briquettes. It indicates that the briquettes are made from purer, more carbon-rich coconut shell material, which is desirable for shisha enthusiasts seeking a clean and consistent heat source.

Combined with high-pressure presses and strict monitoring of the drying process, a high percentage of carbon also indicates the briquette’s hardness and durability. To validate the briquette’s durability, a standard drop-shatter test is involved. First, burn the briquettes under high heat for 10-15 minutes until they are evenly burned on all sides. After 10 – 20 minutes, drop them 3 times from a height of 1 meter. Highly durable briquettes will not show any signs of cracks or shatter following the drop test.

Volatile Matter

Volatile matter refers to the components within the briquette that can turn into gas or vapor when exposed to heat. In the context of coconut charcoal briquettes for shisha, volatile matter primarily includes compounds such as water, hydrocarbons, and other organic materials that are present in the coconut shell charcoal or binders used during production.

Although higher volatile matter can lead to easier and faster ignition, shisha enthusiasts generally prefer coconut charcoal briquettes with lower volatile content for a clean, flavorful, and safe smoking experience.

Coconut charcoal briquettes with lower volatile matter content tend to burn longer and produce less ash. It results in cleaner, odorless smoke that allows the natural flavors of the shisha tobacco to shine through without any undesirable aftertaste. It also produces minimal sparks and smoke which is important for safety, especially in indoor settings.

Ash Content

High quality coconut charcoal briquettes have thin, light ash with small granules and a relatively low ash content between 1.5% and 2.5%, with an average of around 2.0%. This demonstrates that virtually 100% of the briquettes are effectively burned as fuel with minimum wastage and ensures longer burning time.

Quality coconut charcoal briquettes should leave minimal residue after burning. This means that the ash should be fine and powdery rather than chunky or clumpy. Low-residue ash is easier to manage and clean from your shisha or hookah bowl, ensuring a smoother and more enjoyable shisha session.

Ash Color

Premium coconut charcoal briquettes should produce a clean, light grey or white ash when they burn. This light-colored ash is a sign of high-quality charcoal. It indicates that the briquettes are pure and free from impurities, additives, or contaminants.

While it is believed that most preferred ash color for shisha or hookah briquettes is white, some argue that briquettes with white-colored ash do not necessarily have higher performance than those with light grey. It is merely a preference for aesthetic reasons. For this reason, it is not surprising that some markets do not mind what color the ash would be once burned as long as the charcoal is low in ash and provides an enjoyable shisha smoking experience.

An ash color that is too white can be alarming as artificial chemicals might have been added to the mixture to brighten the ash color.

Caloric Content

Coconut charcoal briquettes are a source of energy, and they release heat when burned. The primary purpose of coconut charcoal is to provide a consistent and controlled heat source for shisha. A typical briquette contains around 6,000 to 8,000 Kcal per kg.

Coconut shell charcoal raw material that has been properly carbonized contains high calories which ensures the resulting coconut charcoal briquettes have high calories as well. Premium coconut charcoal briquettes typically have a high calorific value above 7000 Kcal/kg. A higher caloric content indicates a greater potential for heat energy release when they burn.

Burning Time

The burning time of coconut charcoal briquettes varies depending on several factors, including the size of the briquette, its density, and how well it is lit. Larger or denser briquettes may burn longer, while smaller ones may have a shorter burn time. On average, a single coconut charcoal briquette can burn for approximately 45 minutes to 1.5 hours on the shisha or hookah and last up to 2.5 hours on standby.

Moisture Content

It is important to keep the moisture content in the charcoal briquettes to a minimum below 5%. This is to ensure high-efficiency carbonization, whereby briquettes will be fully carbonized when in use resulting in consistent heat output, longer burning time and thin ashes.

Coconut charcoal briquettes that absorb moisture can produce deep cracks when burned. Excessive moisture can also make the briquettes more difficult to light and can lead to uneven burning and reduced heat output during your shisha session. Charcoal briquettes with moisture levels higher than 10% will become softened and mushy 1-2 days after being packed into plastics or boxes.

Proper storage of coconut charcoal briquettes is key for maintaining low moisture content. Store your briquettes in a dry, cool place and keep them sealed in an airtight container to prevent moisture absorption, especially in humid environments.

If you want to verify the moisture content of your coconut charcoal briquettes, you can use a moisture meter designed for charcoal or grilling applications. This can help you ensure that your briquettes are suitable for shisha use.

Odors, Smoke and Sparks

Decent coconut charcoal briquettes do not produce odors, smoke or sparks when burned. This is in line with the clean-burning characteristics of coconut charcoal. Hookah briquettes made of 100% coconut charcoal do not leave any aftertaste in your throat or give you a headache. If you feel any funny feelings in your throat or experience headaches, there is a strong indication that some wood has been added to the mixture which can be detrimental to health if consistently used over time.

It is worth noticing that coconut charcoal briquettes contain tapioca flour as a binding agent which itself is relatively odorless but may emit a mild, temporary odor during the initial few minutes of burning. This odor is usually mild and should dissipate quickly as the briquettes fully ignite and burn. Once the briquettes are fully lit and burning, they should provide a clean and odor-free burn.

Cracks

When inspected from all angles, a good coconut charcoal briquette should not have any gaps or cracks even without being dropped from heights. Cracks can occur in coconut charcoal briquettes for shisha due to various factors during the manufacturing process and storage such as excess moisture, inadequate compression, poor quality of coconut shell raw material, rough handling and transport, poor storage conditions exposing the briquettes to moisture or extreme temperature fluctuations and incorporation of low quality fillers or additives that impact their structural integrity.

Briquettes with deep cracks can lead to uneven and unpredictable burning and increased ash production. They are also more prone to breakage or crumbling during handling and use.

Black Spots

Black spots in coconut charcoal briquettes for shisha are typically areas of the briquette that remain darker in color compared to the surrounding charcoal when burned, also known as “unburned spots”.

Black spots typically occur due to incomplete carbonization whereby not all of the coconut shell material has been converted into pure carbon resulting in areas in the briquettes that are less dense and less efficient at producing heat. In some cases, black spots may be a result of Inconsistent mixing or pressing of the charcoal material during the manufacturing process.

High quality coconut charcoal briquettes for shisha should not produce black spots when burned. Small, isolated black spots may have a minimal impact on the briquette’s performance, while larger or numerous black spots can affect the consistency of the burn, heat output, and overall quality of the shisha session.

Finding a Reliable Supply for Your Coconut Charcoal Briquette Business

Finding a reliable supply is crucial for the growth and sustainability of your coconut charcoal briquette business. Not only is a good supplier able to consistently deliver high quality, premium coconut charcoal briquettes that meet the standard discussed in this article but also highly value the relationships they have established with their clients. In doing so, they will do everything in their power to foster long-term partnerships mutually beneficial for both businesses’ growth and success.

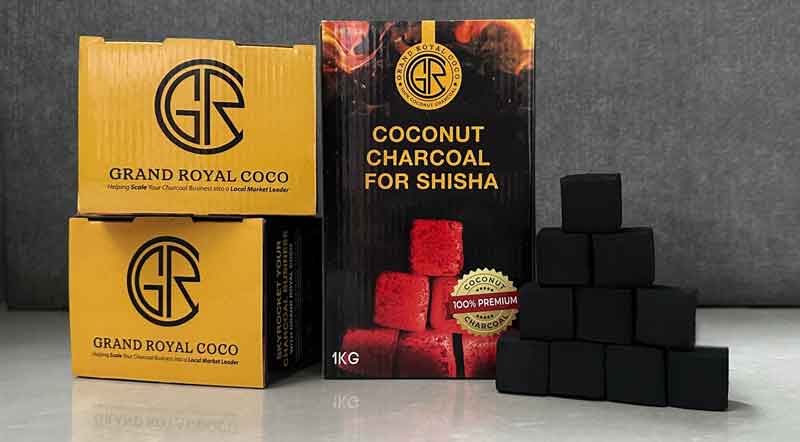

Grand Royal Coco has over 10 years of experience in manufacturing coconut charcoal briquettes. Our charcoal factory produces 4 MT/day of coconut charcoal for shisha and hookah. We place high importance on pre-qualifying our raw materials to ensure we only produce the best quality coconut charcoal briquettes for our clients.

First, we carefully handpick our coconut raw materials from some of the top plantations in Indonesia and thoroughly carbonize the coconut shell in a low oxygen environment to ensure that the resulting coconut shell charcoal has high calories and a high percentage of carbon. This high quality coconut shell charcoal is safely transported to our manufacturing facilities with no exposure to high temperatures, rain and/or salt water that would otherwise affect the moisture content and deteriorate the shell charcoal quality.

At Grand Royal Coco, we implement strict quality control and assurance throughout all stages of our manufacturing processes. We perform random sampling from each batch and put select briquettes under multiple tests to ensure the briquettes we produce have the right ash color, low moisture, long burning time and no cracks. In addition, they should not shatter following the drop tests.

Only qualified batches of briquettes that pass these tests will be packed and shipped to our clients. The coconut charcoal briquettes are packed into boxes in designated areas away from the main production facilities to protect them from excessive charcoal dust. Our packing areas are equipped with good air circulation to prevent any unwanted odor from being absorbed by the coconut charcoal briquettes.

Grand Royal Coco also offers private label or OEM services to help you grow your business to the next level and dominate your market. We understand that every market is different and every business is unique. Therefore, we gladly accept customizations that are specially tailored to your requests let it be shape, size, mixture composition or packaging. We will work together with you to create the perfect charcoal products for your market from start to finish. Your brand, your packaging, our factory.

Book a free consultation with our trusted advisor today and find out how we can help you with your charcoal business.